In this article I look closely at ODM or Original Design Manufacturing.

You’ll save time and money whatever industry you are in by gaining a deep understanding what ODM involves, including the advantages and disadvantages.

We approach the subject from a bicycle components manufacturing angle, since that is our business.

But note that each element discussed generally applies to every industry sector.

LINKS to SECTIONS

ODM vs OEM (& OBM)

OEM – Original Equipment Manufacturer

OEM to ODM Evolution

The ODM Process

OBM – Original Brand Manufacturer

JDM – Joint Design Manufacturer

ODM vs. OEM (& OBM)

In a hurry to know what ODM is in a nutshell, including advantages and disadvantages of the model? Jump to it here.

To appreciate the difference between ODM and OEM, you need to look closely at each of the three pillars of modern manufacturing—OEM, ODM, & OBM.

Each term describes a phase in a continuum; each phase points to a different relationship with the marketplace: a different set of skills and higher level of creative input.

Most factories once only manufactured products on an OEM basis. Many still do. But in the last two decades, as manufacturing has become increasingly high tech, companies have increasingly branched into value-added ODM operations.

In recent years, many companies are, furthermore, expanding into OBM and developing their own brands, as adoption of the Direct to Consumer (D2C) mode of production and distribution gathers pace.

Factories increasingly engage in various combinations of each.

OEM – Original Equipment Manufacturer

An OEM factory has minimal input into any part of a brand’s production process, focusing only manufacturing processes as distinct from design processes.

The factory simply follows the instructions given by the brand or the consulting company ordering a production.

Supplied with the CAD drawings, the relevant engineering data, and instructions covering all details down to the minutiae, they create the product exactly according to specifications and required volume, of course.

Or rather, you hope they would. In an ideal world, yes. But in the real world you need to take full QC responsibility, or have an agent on hand for QC inspection.

OEM factories often outsource certain specific processes that their personnel don’t specialize in. In this way the factory performs a higher-level coordinating function for a brand in that several processes are taken care of under the one management regime.

OEM to ODM Evolution

If you are wondering whether there is a natural path from OEM to ODM, and then even on to OBM, you are on the right track.

A factory that started out as simply OEM a few decades ago would have utilized a high volume, low margin business model. This applies to just about every Taiwan bicycle component manufacturer in the beginning. (Check out the post 4 Key Stages in Pedal Manufacturing)

But over time, the consistent rise in labor costs and consistent flow of new entrants into the OE market has created an increasingly competitive environment, pushing companies to compete on price. The result—increasingly thin margins.

Cost cutting helps, but the real answer is value-added manufacturing which justifies price increases. Companies reduce production volumes; the quality of service increases; average per-unit value increases, often by a lot, depending on how much added value a firm can bring to projects.

Added value is in the form of design services, of course. Hence an evolutionary upgrade to OEM is another way to define ODM.

The key difference between OEM and ODM is the degree of design input from a factory working with a brand under an ODM arrangement.

In contrast to an OEM factory, an ODM factory’s design knowledge and expertise becomes central to a manufacturing project.

As a relatively young company, SCADA’s origins have been in ODM from the beginning in 2012. We produce high-end products in our extensive CNC processing facility, working closely with our partners from the design phase get-go.

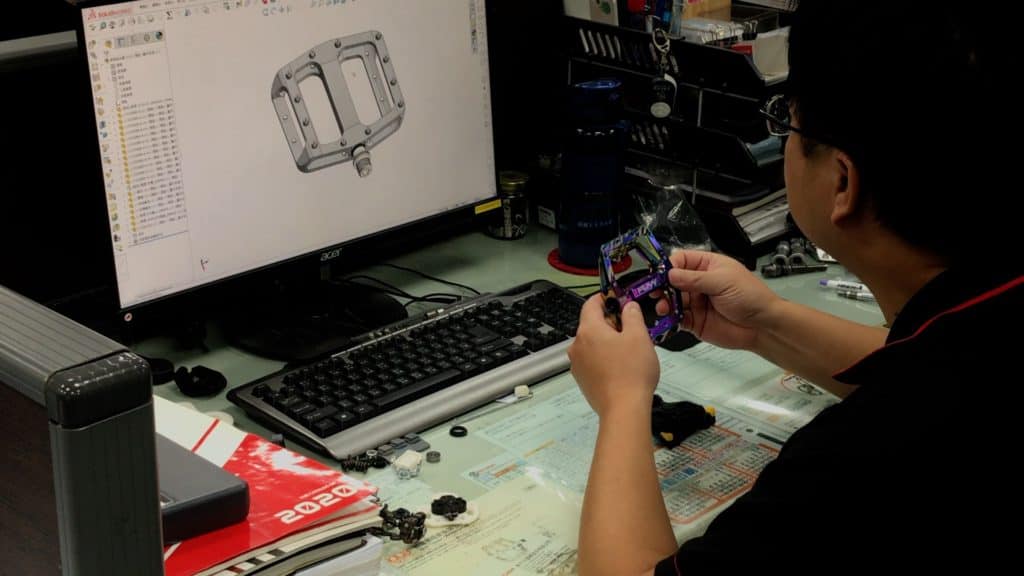

The engineer (above) is working on a CAD design.

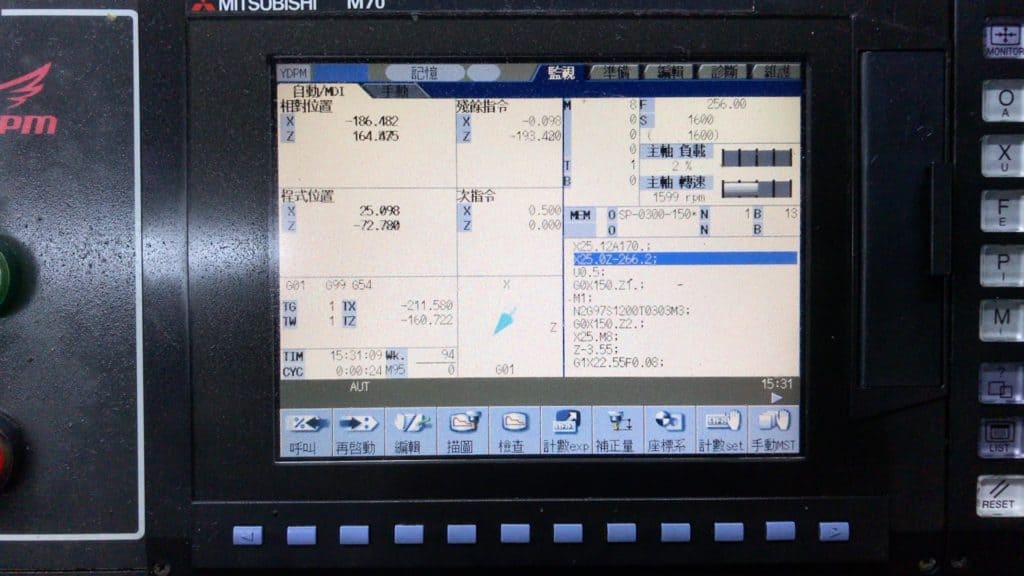

Once finalized, we will convert the design into CNC code (G-Code) for execution by a CNC machine to cut rough aluminum pedal-shaped blanks into the base structure for the finished pedal.

We outsource the anodizing and other finishing processes; the finished pedal bodies are returned for final assembly.

For example, blue-tooth-enabled pedals which measure a rider’s power output in watts, have become a hot item in the market in the late 2010s.

The factory takes their client’s rough ideas and in collaboration with an electronics ODM factory, arrives at a design satisfying their client’s original intent.

They obtain bearings, bushings, axles from other OE producers upstream, then install them into SCADA’s CNC-machined pedal bodies. In this case we produce the pedals on an OEM basis without any design input.

Advantages of ODM

The #1 advantage is in time—and thus money—saved by not having to design a product from scratch. This frees a brand to focus on servicing its customer base.

For example, a brand with expert knowledge of its market niche, the niche’s consumers, and the specifics to grow their business, will rarely wield a similar depth of knowledge of the manufacturing side.

An ODM partner brings the skills and experience to the production process without a contracting brand having to direct any attention or resources to the issue of design.

The cost to the brand will typically be lower since the direct cost to the brand factors in the troublesome process of finding and vetting an OEM—it’s all taken care of in one step.

A brand also leverages an ODM’s economies of scale particularly in circumstances where they have large production runs of items which are sold in smaller lots.

Even if a brand does not purchase large quantities, there is still money to be saved since an item was produced in bulk. A brand may even share a product with a much larger and more well known company.

An important advantage is the ease of making modifications to product design in the future. When a brand is already working with an ODM on an existing product, then the costs of mold, tooling and other changes can be kept to a minimum.

Disadvantages of ODM

Firstly, unless a brand takes advantage of the particular design capabilities of the ODM they partner with, then the product taken to market won’t be unique. This is less an inherent problem with the ODM model, however, as it is with brand strategy.

If the strategy is simply to take market share away from other brands competing in the same space, then there’s no problem.

Of course, superficial differentiation through product packaging and similar tactics means you’ll be thrashing around in an increasingly red ocean, competing on price, watching margins disappear in a race to the bottom.

Plus this course is only good for certain types of products—Amazon springs immediately to mind. Generally speaking, the items that have the most chance of dominating their categories on that platform are the unique, slightly weird products that manage to uniquely fit into a particular niche. That cries out for some seriously focused ODM customization.

There are also limits to the amount of tinkering with colors, packaging, sizing and materials an OEM can tolerate before you are better off diving into a fully-fledged ODM production process.

There is also the question of intellectual property. In most cases, an ODM owns IP rights to your product unless you come to a clearly specified understanding on the issue. It’s more clearcut where creating molds are concerned though: you own the mold and other brands may use it only if you give permission.

In sum, any disadvantages stem from a poorly planned brand strategy rather than the ODM model itself.

The best use for ODM is as a brand-building strategy—brand differentiation comes from exactly defining your USP and then finding the right partner to ensure your product faithfully reflects it.

THE ODM PROCESS

If you’re new to ODM, and looking to choose a partner, be aware of the following points: costs, lead time, communication and obtaining samples are each important variables in the ultimate viability of your product.

Each variable intersects with the other to a degree, but within each, one aspect stands out: the quality of communication.

Quality of Communication

Everyone in business has experienced the head-banging frustration of poor-quality communication which leads to delay upon delay: non-response to communications over the weeks and months.

Language difficulties and the cultural misunderstandings arising from the (mis)use of language are common. One product manager’s word choice and tone is another’s outright rudeness even though no discourtesy was intended.

The best policy is always give the person on the other end the benefit of the doubt.

The real problem lies in delayed replies to questions, along with replies that are too brief or don’t answer your questions.

Conversations at the very outset provide crucial clues to a potential partner’s quality ‘score’. If you must wait a week or more to get thin answers to important questions, those are red flags. Keep vetting potential ODM partners to come up with your short list.

Costs

The cost of a finished product is important. But, take note, you’ll show yourself to be a rookie and thus potentially at a negotiating disadvantage if the first question you ask of an ODM is “How much is the (final) product?”

There are a bunch of factors influencing the final price. The most important, by far, is the quality of your ODM supplier.

You need to undertake a detailed evaluation of each supplier on your shortlist. A quality evaluation includes visiting their facility, inspecting licenses and certifications, and simply getting a feel for the place.

You’ll want to see a clean record with local and federal government agencies: can the factory operate comfortably with minimal chance of an arbitrary shutdown? What is their record on labor relations?

Being able to conduct a detailed review of the supplier’s track record, past transactions with its previous clients and financial records would help although most companies won’t provide that level of detail.

Lead Time

Getting your product to market for your targeted season is central to the cost equation.

But it all depends on your ODM partner—can you rely on their estimates which depends a lot on their ability to deliver on time?

Look into their history in respect of delayed production. Sure, it’s often not easy to get this information. But, the harder you work at this stage, the more likely you are to make a good call.

You should have a good idea of their entire supply chain, from upstream, to the time the container arrives at your warehouse. You can then make your own informed evaluation on how much time will be required from start to finish.

Getting Samples

Inspecting product samples is essential.

That’s how you confirm that your potential ODM partner can actually create your product; you’ll also get some idea of the quality of their workmanship.

I say “some” because a factory may well send you a carefully curated set of examples.

Unless you have years or decades of experience in dealing with either OEM or OBM factories or cooperating suppliers, then often the best course is to find an agent. In the Taiwan bicycle supply chain, Trading Companies play that role.

Your task then becomes thoroughly vetting potential trading companies, treating them as you might a factory.

Finally

“Do your homework” the cliche goes. But it’s true. Do your homework.

You may not come out of the experience richer than you went in. But if you go easy on anything at this stage, you may well come out poorer for it.

Putting all the results of your investigations together you should be able to see at a glance which ODMs would most likely make the best partners.

- What is the total production turnaround time?

- What are the nitty-gritty details of customization? How does that really work?

- How responsive are they to communication?

- Are your expectations realistic in relation to your overall business goal once you have decided on a supplier?

Your skill in selecting the right ODM is the key to your success.

OBM – Original Brand Manufacturer

OBM is the most mature phase of the OEM-ODM-OBM continuum in which factories design and manufacture products under their own brands.

Taiwan’s factories all began on an OEM basis, some as long as 70 years ago.

Giant and Merida are probably the most well-known bicycle industry OEM companies that have top tier, world class Own Brand bikes. Both companies also are extensively involved in ODM, working with many of the most prestigious brands in the bicycle industry.

Giant has long produced Trek’s frames and forks; they’ve done productions for Colnago and Yeti as well. Merida is most well-known as Specialized’s frame-maker.

Both companies also have their own long-established well-regarded brands.

A lesser know example is Masslord’s Ibera brand. Anyone buying a water bottle cage on Amazon will likely have bought an Ibera model. Taipei Cycle showgoers would note the Ibera booth sharing a wall with the Masslord booth—one company, two booths.

JDM – Joint Design Manufacturers

I’ll mention JDM, as it often comes up, particularly in relation to Electronics Manufacturing Service providers (EMS).

Think of Joint Design Manufacturing as a variation on, or even as an extension to, ODM. The company outsourcing a product works in close cooperation across all aspects of design and manufacturing with the manufacturing entity.

Teams from both sides work together as one tackling obstacles, working together on design revisions and testing implementation, through to work flows on a factory floor and more.

This model is potentially available as a set of functions uniting two companies in terms of a particular project. However, JDM companies are attuned to the particular requirements of this mode of cooperation, and therefore specialize in it.

The trend to electrification in the form of eBikes across all bike categories may well transform bicycles from mere bikes into a sub-class of EVs or Electric Vehicles. Perhaps we are headed towards a new era of partnerships in the style of JDM, and away from the sort of ODM cooperation that has defined ODM so far.

FINAL REMARKS

Whether you are dealing with potential OEM, ODM, or OBM suppliers, research is the key to identifying the best option.

Brands putting maximum effort (and solid budget) behind the identification process will massively reduce the chance of a costly mistake.